How Forged Wheels Reduce Brake Dust on Electric Vehicles

- Brinal Chua

- 3 days ago

- 7 min read

Electric vehicle ownership in Singapore has increased dramatically over the past three years. From Tesla Model 3s navigating Shenton Way to BYD Seals cruising along Marina Bay, these vehicles represent a shift in how Singaporeans approach transportation. Yet EV owners quickly discover an unexpected maintenance challenge: persistent brake dust accumulation on wheels.

After three decades managing automotive brands across Southeast Asia, I've observed how regenerative braking systems create unique wheel maintenance patterns. Understanding this difference explains why wheel material and construction method matter more for electric vehicles than most owners realize.

Key Takeaways

Regenerative braking in EVs creates different thermal cycling patterns than combustion vehicles

Forged aluminum wheels dissipate heat more effectively, reducing brake dust adhesion

Denser grain structure in forged wheels resists surface contamination and simplifies cleaning

Singapore's tropical climate accelerates brake dust bonding to wheel surfaces

Proper wheel finish selection significantly affects long-term maintenance requirements

Table of Contents

Understanding Brake Dust in Electric Vehicles

Brake dust consists primarily of iron particles from brake rotors, friction material from brake pads, and carbon residue from binding agents. When brakes engage, temperatures at the rotor-pad interface reach 300-500°C, vaporizing these materials and depositing them on wheel surfaces.

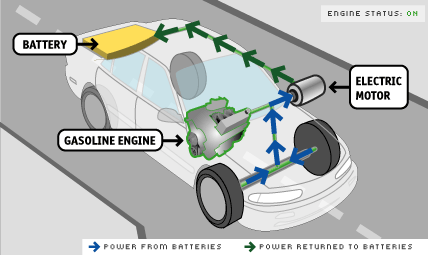

Electric vehicles use regenerative braking to recover kinetic energy during deceleration, handling 60-80% of routine braking events. This significantly reduces friction brake usage compared to combustion vehicles. Less friction brake usage should logically mean less brake dust.

However, EV owners in Singapore frequently report more visible brake dust accumulation than expected. This has a straightforward explanation: intermittent brake usage combined with tropical climate conditions creates optimal circumstances for brake dust adhesion.

When friction brakes engage infrequently, they don't reach optimal operating temperatures consistently. Brake pads may glaze slightly, altering wear characteristics. Rotors develop surface oxidation between braking events, changing how dust particles generate and disperse.

Singapore's high humidity (typically 70-90%) accelerates this process. Moisture causes iron particles in brake dust to oxidize rapidly, creating rust compounds that bond more aggressively to wheel surfaces than non-oxidized particles.

How Regenerative Braking Changes Maintenance

Tesla Model 3 and Model Y vehicles employ single-pedal driving modes that maximize regenerative braking. Drivers rarely touch the brake pedal during normal city driving. The friction brakes only engage during emergency stops or final-speed reductions below approximately 8 km/h.

This usage pattern means friction brakes might only engage 10-15 times per week for typical Singapore driving, versus 100+ times weekly in combustion vehicles. When brakes do engage, they often do so from lower speeds with less kinetic energy to dissipate, creating different thermal profiles.

BYD Seal, Polestar 2, and Hyundai Ioniq models employ similar regenerative braking strategies. The result remains consistent: friction brakes operate less frequently but under variable conditions that don't always optimize for minimal dust generation. These intermittent activations create the conditions for increased visible dust accumulation.

Why Forged Aluminum Resists Contamination

Cast aluminum wheels are manufactured by pouring molten aluminum into molds. The cooling process creates a crystalline structure with inherent porosity at microscopic levels. These tiny surface imperfections provide anchor points for brake dust particles.

When iron-rich brake dust lands on cast wheel surfaces, particularly heated surfaces, particles can partially embed in these microscopic imperfections. Singapore's humidity accelerates oxidation, effectively welding particles to the wheel surface through rust formation.

Forged aluminum wheels begin as solid billets compressed under extreme pressure, creating denser material with aligned grain structure. This forging process eliminates the microscopic porosity found in cast wheels. The resulting surface presents fewer opportunities for particle adhesion.

A forged wheel's denser surface structure means brake dust particles sit on the surface rather than partially embedding within it. Water with mild soap can remove these particles more effectively because they haven't mechanically bonded to the surface structure.

This difference becomes apparent during routine washing. Cast wheels typically require dedicated wheel cleaners and stiff brushes. Forged wheels often clean adequately with the same soap and pressure used on vehicle paint, requiring less mechanical agitation.

Heat Management and Adhesion

Heat affects how brake dust adheres to wheel surfaces. When brake dust particles land on hot surfaces, they bond more aggressively. The thermal energy activates binding agents in brake pad compounds, creating stronger adhesion.

Forged aluminum wheels, with their denser grain structure, conduct and dissipate heat more efficiently than cast wheels. During braking events, forged wheels draw thermal energy away from brake components faster, reducing peak surface temperatures.

Lower peak temperatures mean brake dust particles landing on forged wheel surfaces encounter less thermal energy to activate adhesion mechanisms. The particles remain more loosely attached, simplifying subsequent cleaning.

This advantage compounds over time. Cast wheels that accumulate multiple layers of brake dust develop increasingly difficult cleaning requirements. Forged wheels resist this progressive buildup. Because initial brake dust adhesion is weaker, regular washing prevents accumulation from developing into stubborn deposits.

Singapore Climate Considerations

Singapore's tropical climate averages 27-31°C year-round with humidity consistently above 70%. These conditions accelerate chemical reactions, particularly oxidation processes involving iron particles.

Brake dust contains significant iron content from rotor wear. When iron particles land on wheel surfaces in high-humidity environments, oxidation begins within hours. This rust formation acts as an adhesive, bonding particles to wheel surfaces and to each other.

Cast wheels, with their more porous surface structure, provide ideal conditions for this oxidation process. Moisture penetrates microscopic surface imperfections, creating optimal environments for rust formation. Once rust forms, removing particles requires disrupting the rust bond, typically requiring acidic wheel cleaners.

Forged wheels' denser surface structure limits moisture penetration, slowing oxidation processes at the particle-surface interface. While rust still forms on the dust particles themselves, the bond between rusted particles and the wheel surface remains weaker.

Coastal areas near Marina Bay or East Coast Park introduce additional salt exposure. Salt accelerates corrosion processes, making brake dust removal even more challenging on cast wheels. Forged wheels demonstrate better resistance to this combined moisture-salt-brake dust environment.

Finish Selection for Reduced Maintenance

Wheel finish selection significantly affects long-term maintenance requirements for electric vehicle owners in Singapore.

Powder-Coated Finishes:

Powder coating creates a uniform surface layer over the aluminum substrate, providing the smoothest possible surface with minimal mechanical anchor points for brake dust particles. Quality powder-coated finishes on forged wheels represent the easiest maintenance option. Our color and finish range includes multiple powder-coated options specifically selected for tropical climate durability.

Brushed and Satin Finishes:

Brushed finishes create directional texture, providing slightly more surface area for brake dust adhesion compared to smooth powder coats. However, brushed finishes on forged wheels still outperform smooth finishes on cast wheels due to underlying material density advantages. The AR-i68, AR-i75, and AR-i57 models from our Iconic Series work well with these finishes.

Polished Finishes:

High-polish finishes show brake dust most visibly due to high contrast between polished aluminum and dark brake dust. While the smooth surface doesn't promote adhesion, these finishes require more frequent attention to maintain appearance.

Ceramic Coating Application:

Applying ceramic coating over any wheel finish creates an additional protective layer that further reduces brake dust adhesion. Brake dust particles struggle to adhere to ceramic-coated surfaces, and water beads off effectively. For Singapore EV owners willing to invest in initial ceramic coating application, maintenance requirements drop substantially.

Our Precision Series wheels undergo rigorous quality control processes ensuring consistent material density and surface characteristics across all models. Understanding our philosophy on engineering integrity helps explain why we emphasize these practical ownership benefits.

Ready to reduce brake dust maintenance on your electric vehicle? Contact us for detailed specifications on forged wheel options, or reach out via WhatsApp to discuss fitment and finish selection for Singapore conditions.

Frequently Asked Questions

Do forged wheels completely eliminate brake dust on EVs?

No, but they significantly reduce adhesion strength. All wheels accumulate brake dust; forged wheels make it easier to remove during regular washing without harsh chemicals or aggressive scrubbing due to denser surface structure.

How often should I clean forged wheels on my Tesla in Singapore?

Every 2-3 weeks maintains good appearance with minimal effort. Use pH-neutral soap and soft brushes. Monthly ceramic coating maintenance maximizes long-term ease. Frequency depends on driving patterns and brake usage intensity.

Will forged wheels work with my EV's regenerative braking system?

Yes, forged wheels are fully compatible with all regenerative braking systems. They don't affect regenerative function; they simply manage heat better during friction brake engagement, reducing brake dust adhesion when friction brakes activate.

What finish resists brake dust best on electric vehicles?

Powder-coated finishes provide smoothest surfaces with minimal brake dust adhesion. Ceramic coating over any finish further improves resistance. Brushed and satin finishes balance aesthetics with maintenance. Polished finishes show dust most visibly.

Are forged wheels worth the cost for brake dust reduction alone?

Brake dust advantages represent one benefit among many. Forged wheels also reduce unsprung weight (improving range and handling), dissipate heat better, and last longer. Combined benefits justify investment; brake dust reduction alone may not.

Engineering Solutions for Real Ownership Challenges

Electric vehicle ownership in Singapore presents unique maintenance considerations. Brake dust accumulation, counterintuitively worse than expected given reduced friction brake usage, represents one of these unexpected challenges.

Forged aluminum wheels address this through fundamental material properties rather than surface treatments alone. Denser grain structure, superior heat dissipation, and reduced surface porosity create measurable advantages for Singapore's tropical climate.

At Aura Forged, we've spent three decades understanding how vehicles perform in Southeast Asian environments. Learn more about our approach to engineering-focused wheel development, or explore our complete ordering process.

Looking to reduce brake dust maintenance on your electric vehicle? Contact us directly or reach out via WhatsApp for consultation on forged wheel options specific to your EV model.

References

Society of Automotive Engineers (SAE International). (2023). "Regenerative Braking Systems and Brake Wear Characteristics in Electric Vehicles." SAE Technical Paper Series.

National Environment Agency Singapore. (2024). Climate and Weather Statistics.

Materials Science and Engineering Journal. (2023). "Surface Porosity and Contamination Adhesion in Cast vs Forged Aluminum Alloys."

Comments